Txais tos rau CHUANGRONG

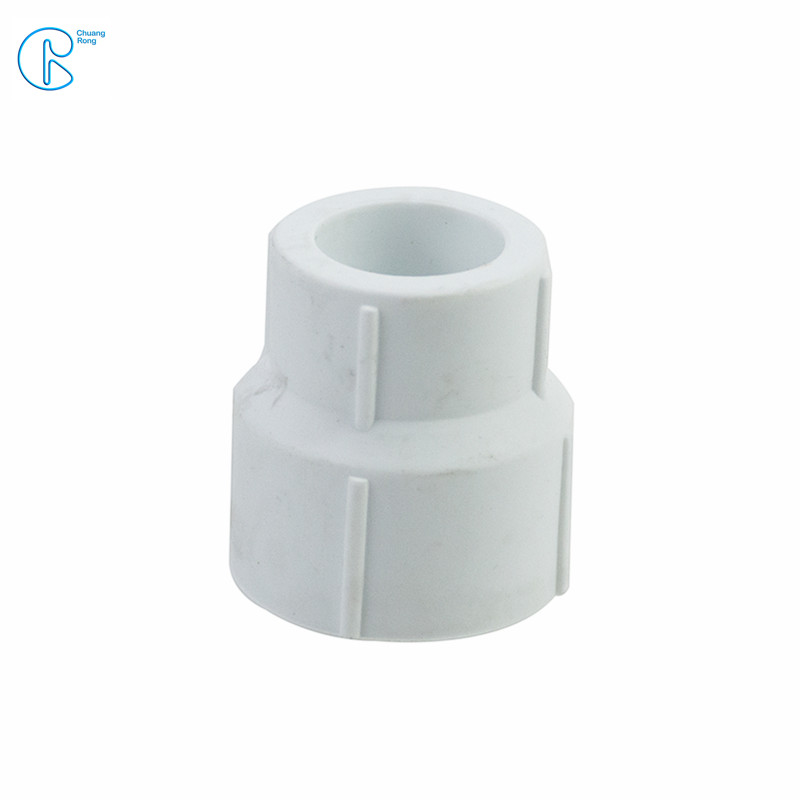

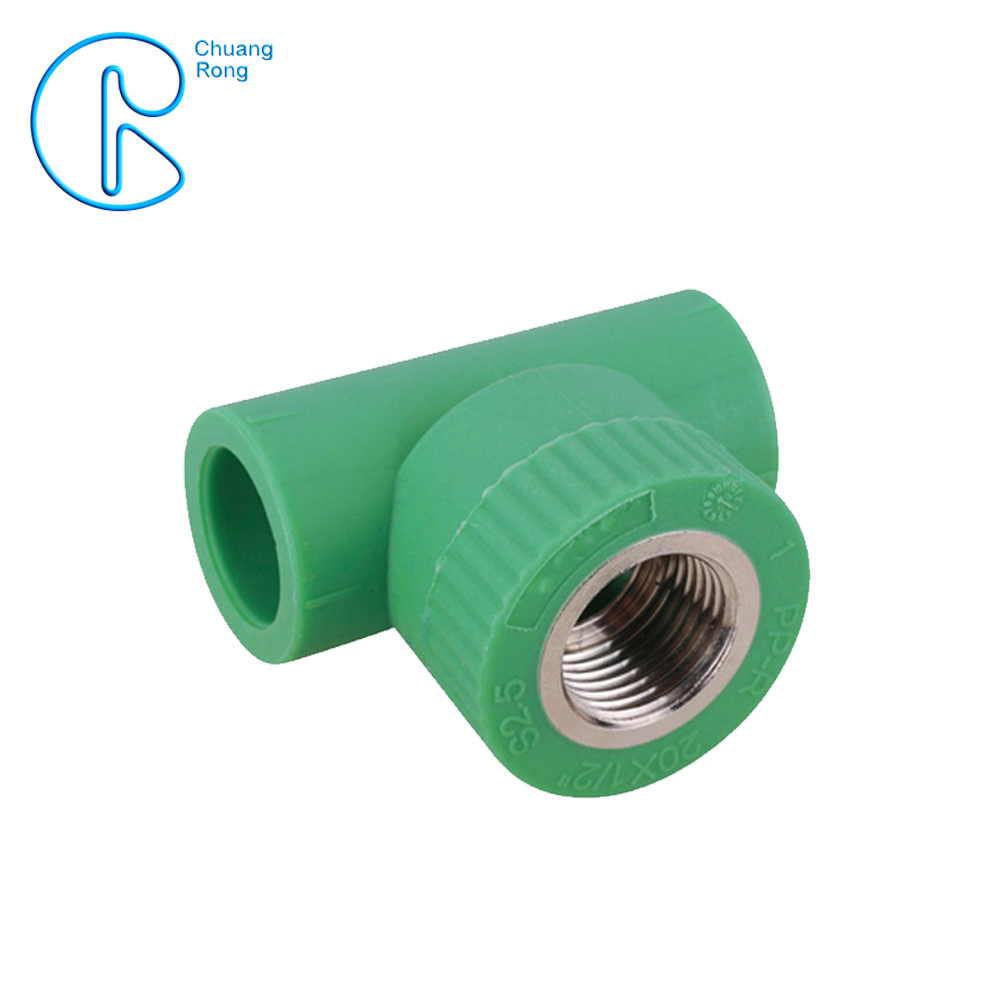

Ntsuab PPR Reducer Hauv Siab 25 Rau Cov Cuab Yeej Cuab Yeej / Cua Txias

Cov lus qhia ntxaws

| Khoom npe: | PPR Reducer | Cov duab: | Reducer |

|---|---|---|---|

| Lub taub hau Code: | Hloov | Xim: | Ntsuab |

| Hom Tshuaj: | CR | Qhuav kub: | -40 - +95 ° C |

Product Description

Ntsuab PPR Reducer Hauv Siab 25 Rau Cov Cuab Yeej Cuab Yeej / Cua Txias

Paub txog kev sib txuas ntawm cov kav dej lossis fittings ntawm cov kab sib txawv, lub qhov (socket) welder txuas, yooj yim thiab yooj yim, nyab xeeb thiab ib puag ncig zoo.

| Lub cev muaj zog | Hom Tus nqi* | Chav tsev | TestMethod | |

| Qhov ntom | 905 ua | kg/m3 | TS EN ISO 1183 | |

| Melt Flow Rate | (230 ℃ / 2.16kg) | 0.25 | g/10 min | TS EN ISO 1133 |

| Tensile Stress ntawm Yield | (50 hli / min) | 25 | MPa | ISO 527-2 |

| Tensile Strain ntawm Yield | (50 hli / min) | 10 | % | ISO 527-2 |

| Modulus ntawm Elasticity nyob rau hauv Tension | (1 hli / min) | 900 | MPa | ISO 527 |

| Charpy Impact Strength, notched | (+ 23 ℃) | 40 | kJ/m2 | ISO 179/1 eA |

| Charpy Impact Strength, notched | (0 ℃) | 4 | kJ/m2 | ISO 179/1 eA |

| Charpy Impact Strength, tsis muaj zog | (-20 ℃) | 2 | kJ/m2 | ISO 179/1 eA |

| Txhais tau tias Linear Thermal Coefficient ntawm Expansion ntawm 0 ° C txog 70 ℃ | 1.5 | *10-4K-1 | TIAB SA 53752 | |

| Thermal conductivity | 0.24 ib | WK-1m-1 | DIN 52612 Ntu 1 | |

Specification

| Kev piav qhia | d | d1 | D | D1 | L |

| dn25x 20 | 20 | 20 | 34 | 28 | 37 |

| ib 32x20 | 32 | 20 | 43 | 28 | 41 |

| d032x 2 | 32 | 20 | 43 | 34 | 53 |

| dn40x 20 | 40 | 20 | 53 | 28 | 48 |

| dn40x 20 | 40 | 20 | 53 | 34 | 48 |

| wb 40x32 | 40 | 32 | 53 | 43 | 63 |

| dn50x 20 | 50 | 20 | 67 | 28 | 56 |

| dn50x 20 | 50 | 20 | 67 | 34 | 54 |

| ib 50x32 | 50 | 02 ib | 67 | 43 | 54 |

| wb 50x40 | 50 | 40 | 67 | 43 | 54 |

| wb 63x20 | 63 | 20 | 84 | 28 | 68 |

| wb 63x20 | 63 | 20 | 84 | 34 | 66 |

| wb 63x32 | 63 | 32 | 84 | 43 | 66 |

| wb 63x40 | 63 | 40 | 84 | 53 | 66 |

| wb 63x50 | 63 | 50 | 84 | 67 | 66 |

| wb 75x40 | 75 | 40 | 100 | 53 | 68 |

| wb 75x50 | 75 | 50 | 100 | 67 | 74 |

| wb 75x63 | 75 | 63 | 100 | 84 | 70 |

| wb 90x63 | 90 | 63 | 120 | 84 | 82 |

| wb 90x75 | 90 | 75 | 120 | 100 | 83 |

| wb 110x63 | 110 | 63 | 148 | 84 | 88 |

| wb 110x75 | 110 | 75 | 148 | 100 | 98 |

| wb 110x90 | 110 | 90 | 148 | 120 | 95 |

| dn125x110 ua | 125 | 110 | 150 | 141 | 100 |

| wb 160x125 | 180 | 125 | 204 | 150 | 110 |

Qhov zoo

Perfect Thermal Fusion Joints: Qhov tshwj xeeb qhov (socket-fusion vuam) txheej txheem tsim ib qho kev sib koom ua ke, cov ntaub ntawv pov thawj uas muaj zog zoo li cov yeeb nkab nws tus kheej, kom ntseeg tau tias qhov kawg ntawm lub cev.

Exceptional Heat Resistance: Zoo tagnrho rau kev siv dej kub thiab dej txias. muaj peev xwm tiv taus qhov kub thiab txias mus txog 70 ℃ thiab siab dua rau lub sijhawm luv luv.

Superb Hygiene and Water Purity: Inert material tiv thaiv corrosion thiab scaling, kom tsis txhob saj, tsw, los yog paug ntawm cov dej haus, thiab tswj cov dej zoo.

Lub neej ua haujlwm ntev & Durability: Kev ua haujlwm zoo heev rau tshuaj lom neeg thiab electrochemical corrosion guarantees lub neej kev pab cuam tshaj 50 vears nyob rau hauv ib txwm ua hauj lwm tej yam kev mob.

Zog txuag thiab rwb thaiv tsev; Tsawg thermal conductivity txo cov cua sov hauv cov kab dej kub, txuag hluav taws xob, thiab tiv thaiv qhov hws hauv cov kab dej txias.

Lub teeb yuag thiab yooj yim Installation: Qhov tseem ceeb sib dua li hlau pioes. ua kev thauj mus los thiab kev teeb tsa sai dua, yooj yim dua, thiab siv nyiaj ntau dua.

Daim ntawv thov

CHUANGRONG muaj pab pawg neeg ua haujlwm zoo nrog kev paub nplua nuj. Nws lub hauv paus tseem ceeb yog Kev Ncaj Ncees, Kev Ua Haujlwm thiab Ua Tau Zoo. Nws tau tsim kev lag luam kev sib raug zoo nrog ntau dua 80 lub teb chaws thiab thaj chaw hauv kev lag luam txheeb ze. Xws li Tebchaws Meskas, Chile, Guyana, United Arab Emirates, Saudi Arabia, Indonesia, Malaysia, Bangladesh, Mongolia, Russia, Africa thiab lwm yam.

Txais tos tiv tauj peb kom paub meej cov khoom thiab kev pabcuam tshaj lij.

Thov xa email rau: chuangrong@cdchuangrong.comlos yog Tel:+86-28-84319855

Xa koj cov lus rau peb:

Cov khoom qeb

-

Xov tooj

-

E-mail

-

Whatsapp

-

Skype

-

Sab saum toj